Grounding System untuk Pengisian Truk Tangki Pabrik Kimia dan Petrokimia

The chemical and petrochemical sector relies on the efficient transportation, handling and processing of many hazardous and highly flammable chemical products.

Supply chain activities like the transfer of chemicals to and from tank trucks and railcars; filling, mixing and blending in drums or IBCs, and minor operations like dispensing solvents from safety cans generate hazardous levels of static electricity. The most effective static control solution of eliminating the risk of fires and explosions caused by static electricity is to use modern fit for purpose static control equipment.

kegiatan rantai pasokan seperti transfer bahan kimia ke dan dari truk tangki dan gerbong; mengisi, pencampuran dan pencampuran dalam drum atau IBCs, dan operasi minor seperti pengeluaran pelarut dari safety container, menghasilkan tingkat berbahaya listrik statis. Solusi kontrol statis yang paling efektif menghilangkan risiko kebakaran dan ledakan disebabkan oleh listrik statis adalah dengan menggunakan fit modern untuk tujuan peralatan kontrol statis.

Tank Truck Filling & Emptying

Tank Truck Filling & Emptying

Static electricity can lead to large voltages on tank trucks.

Listrik statis dapat menyebabkan tegangan besar di truk tangki.

Mobile Grounding for Trucks

Mobile Grounding for Trucks

Grounding for trucks in locations where installed grounding systems are not present.

~Landasan untuk truk di lokasi di mana sistem grounding yang tidak terpasang dengan baik

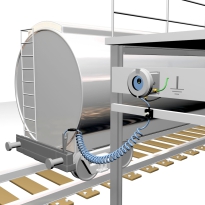

Railcar Filling & Emptying

Railcar Filling & Emptying

Grounding and interlocks preventing charge accumulation on the tanks of railcars.

~Grounding dan interlock mencegah akumulasi muatan pada tangki dari gerbong

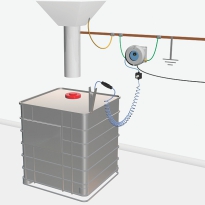

Filling IBCs & Large Containers

Filling IBCs & Large Containers

The manual filling of portable drums and vessels can result in incendive static spark discharges.

~Pengisian manual drum portabel dan kapal dapat mengakibatkan incendive percikan kotoran statis

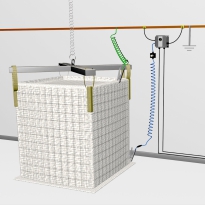

FIBC Filling & Emptying

FIBC Filling & Emptying

Grounding and interlocks for Type “C” Big Bag operations.